SuperMIG®

Welding System

SuperMIG® combines Plasma Arc and MIG welding in one torch, powered by AI for efficient autonomous operation.

SuperMIG® Overview

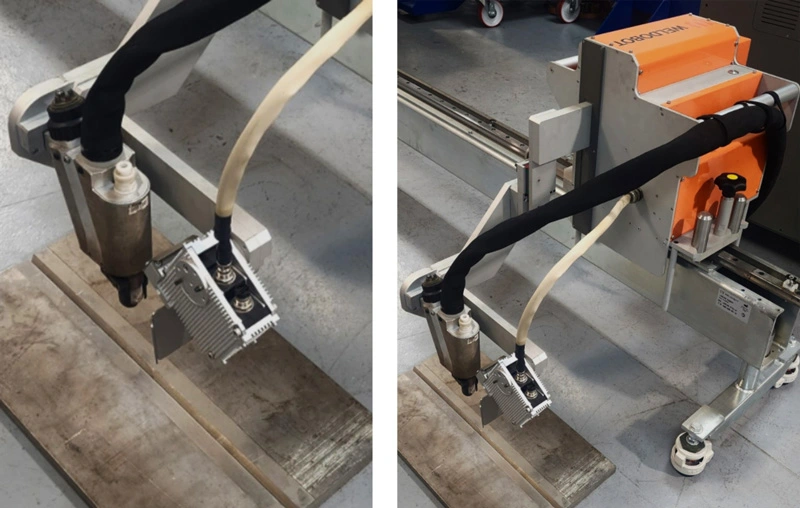

The SuperMIG® welding system is built on a unique hybrid combination of Plasma Arc Welding (PAW) and Gas Metal Arc Welding (GMAW) processes, protected by a registered patent. The system consists of two main components: the Welding Torch and the Welding Control Module (SuperMIG® WCM).

By merging the power of PAW and GMAW, this innovative hybrid technology delivers superior performance, including increased welding speed, deeper penetration, and a minimized Heat-Affected Zone (HAZ).

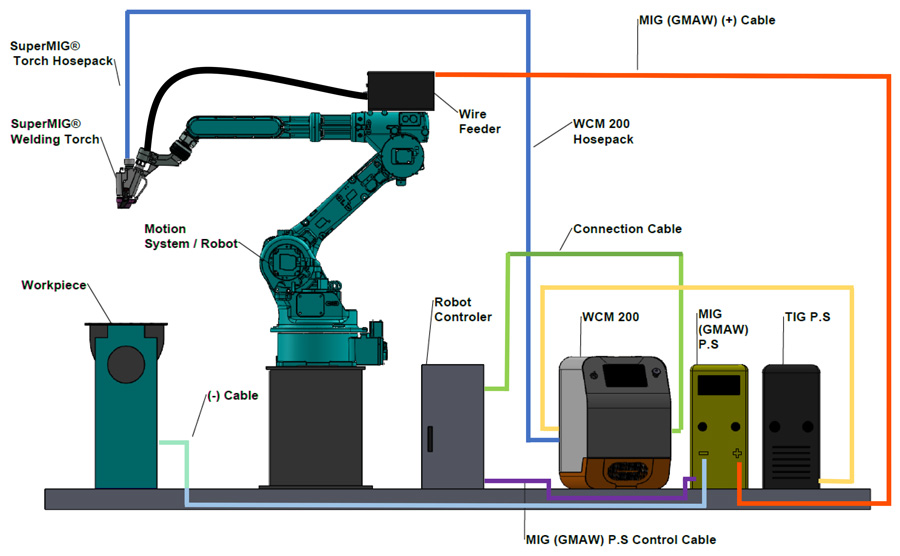

System Configuration

Welding Control Module

(SuperMIG® WCM)

The SuperMIG® WCM is a master controller for the Welding arcs, Plasma and MIG . It integrates the plasma arc power source, GMAW power source, coolant unit, and the interaction with the robotic system. Additionally, the WCM manages and monitors welding gases flow rates during operation. The SuperMIG® WCM is designed to be integrated with a wide range of robots and welding power supplies brands.

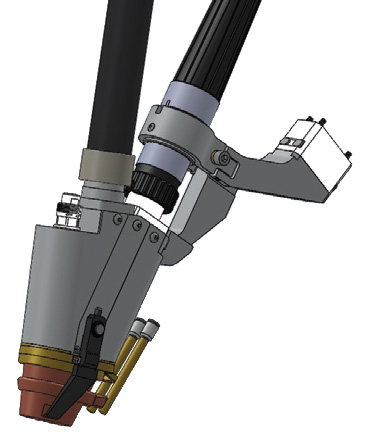

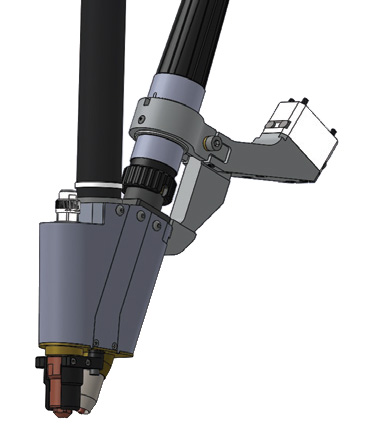

Heavy Duty (HD)

HD Slim (HDS)

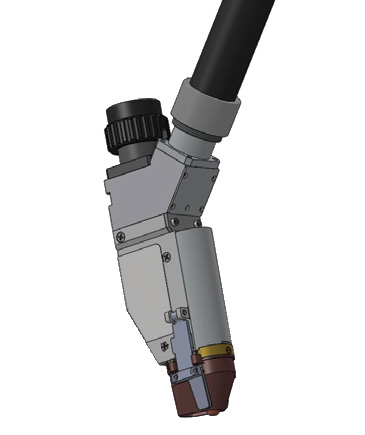

Medium Duty

Welding Torches

The SuperMIG® Welding Torch supports filler wire diameters up to 0.0625” (1.6 mm). Its electrically insulated, water-cooled, and pre-aligned welding head ensures consistent performance and easy maintenance.

The SuperMIG® Welding torch family includes various models such as HD (Heavy Duty), HDS (Heavy duty Slim), and MD (Medium Duty).

How it Works

The SuperMIG process utilizes a plasma arc to provide the energy required to penetrate and melt the base material, while the MIG arc supplies the filler metal to form the weld.

These two arcs operate simultaneously within the SuperMIG torch, working together to enhance the welding process. A magnetic field, integrated into the torch nozzle, is employed to control the distance between the two electric arcs, ensuring stability and maintaining the quality of the weld.

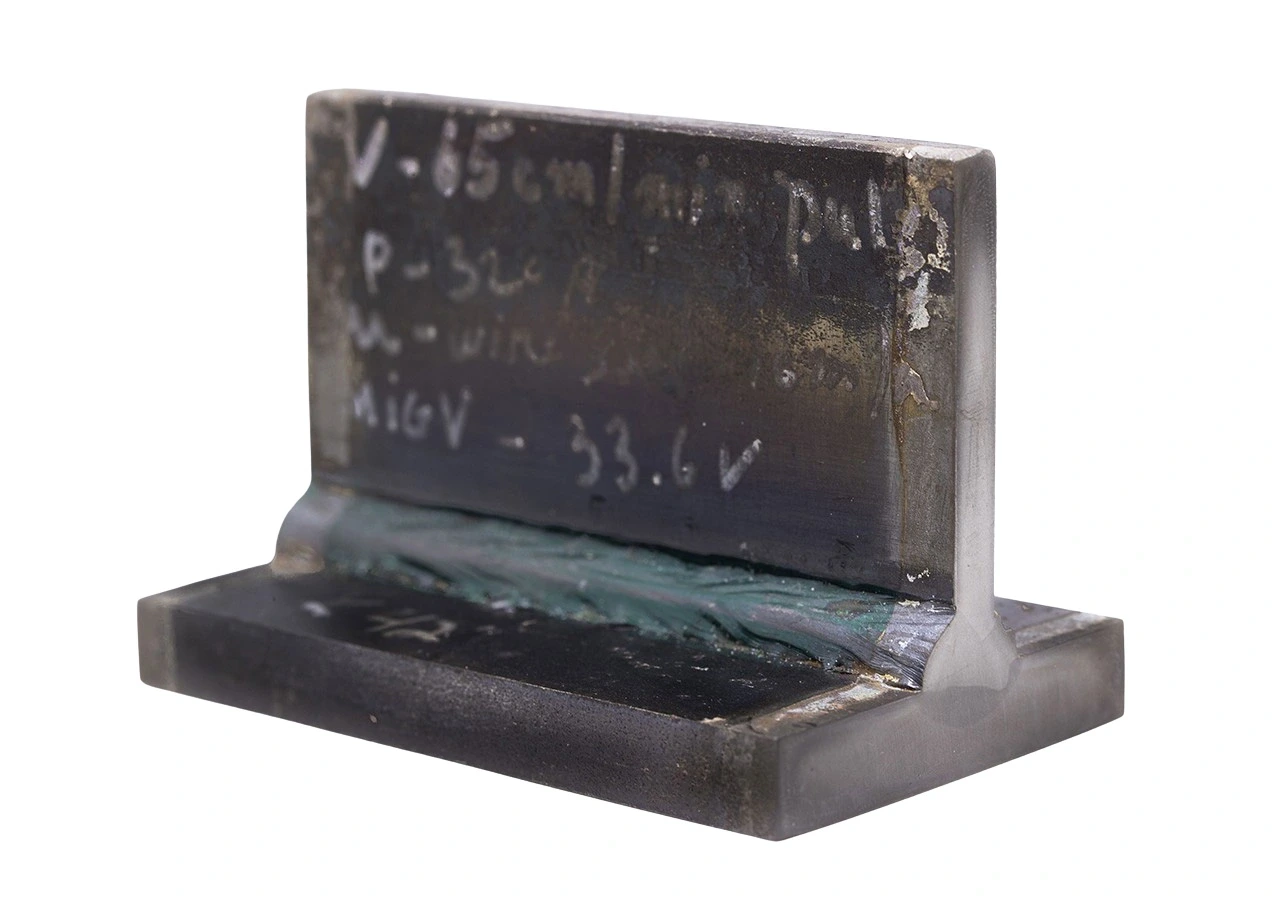

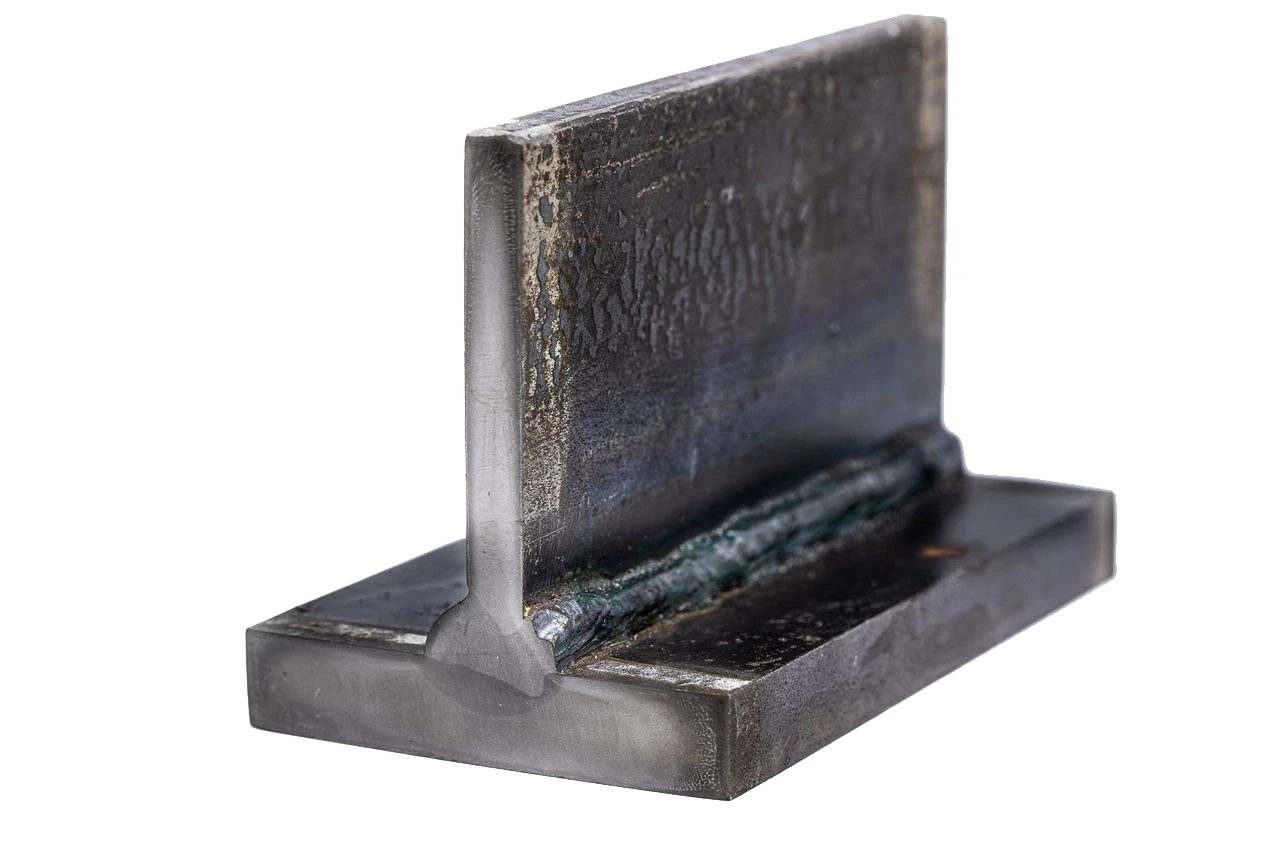

Macrostructural Appearance - Plasma/GMAW and GMAW

Main Features and Capabilities

Single-pass welding of up to 15mm (9/16 inch) thick steel

No edge preparation or beveling required

Single-sided welding – no need for two-sided operations

Due to speed, metal characteristics hardly altered or compromised

Heat affected zone is minimal

Slag removal is not required

Filler metal consumption is decreased by over 50%

50% Improvement in productivity

Quick ROI (return on investment)

AI-Enhanced Laser Tracking:

Elevating Welding Precision and Quality

Integrating an AI-enabled laser tracker into the SuperMIG process enhances efficiency, precision, and quality control. The system monitors the welding surface, dynamically adjusting both the torch position and welding parameters in real time to ensure consistent weld quality, even with complex geometries. This reduces human error, optimizes energy usage, and minimizes material waste.

The AI detects defects such as undercutting or porosity and fine-tunes welding parameters to prevent issues. By analyzing data from previous welds, it continuously optimizes settings to improve productivity. Additionally, the system logs detailed weld data, supporting performance analysis and continuous improvement while minimizing manual intervention and downtime.

Welding Quality Compliance

WELDOBOT’s SuperMIG® was designed to produce quality welds on a variety of ferrous-based alloys and in wide array of welding conditions.

SuperMIG® welds are regularly tested by 3rd party laboratories, such as TUV Nord – Germany/Poland, Metallabs/Applied Metallurgy – Israel, and Henry J. Yeager Laboratories – United States, and continue to produce satisfactory tensile, guided-bend, hardness, and impact test results.

SuperMIG® welds meet international standards and qualification requirements, ensuring high-quality and reliable performance across various industries.

Product specifications

| SuperMIG® WCM (Welding Control Module) Specifications | ||

|---|---|---|

| Medium Duty | Heavy Duty | |

| Plasma Power Capacity – 100% load | 200A | 360A |

| Welding Gases Requirements | ||

| Gas Pressure | 3-4 bar (43-58psi) | |

| Gas Flow Rate | 1-7 LT/min – Plasma Gas 5-23 LT/min – MIG Shielding Gas 5-45 LT/min – Overall Shielding Gas |

|

| Gas Type | Plasma Gas - Argon (welding grade) MIG Shielding Gas – Customer Specified Overall Shielding Gas – Customer Specified |

|

| Cooling Liquid Flow Rate and Pressure | 1.4 LT/min @ 8.9 Bar | |

| Cooling Liquid Capacity/Volume | 11-12 LT | |

| Operation Temperature Range | 5°C (41°F) – 45°C (113°F) | |

| Storage Temperature Range | -10°C (13°F) – 55°C (131°F) | |

| Electrical Connection | 1 Phase / 230VAC / 50-60Hz, 3 pin connector | |

| Power Consumption | 1.5 kVA @ 100% duty cycle | |

| Max. External Dimensions – S-MIG®, WCM mm (Inches) | Depth: 850 mm (33.5") Width: 460 mm (18.1") Height: 700 mm (27.6") |

|

| SuperMIG® WCM Max. Weight, Kg - (Lbs) | 60 kg (132 lbs) | |

| Note: All specifications are subject to change for product improvement without notice. | ||

Welding Cost Comparison

The following comparison table presents the welding cost of Weldobot’s SuperMIG in comparison to other conventional welding processes. The table outlines a sample application: butt welding of 10mm (3/8”) carbon steel, with a weld length of 8m (26’), a production batch is 1000 units, and an average manpower cost of €40/hour.

| Butt Welding Carbon Steel 10 mm | Welding Technology | |||

| Activity and cost | Submerged Arc | Plasma | MIG | SuperMIG |

| Length of each parts (meter) | 8 | 8 | 8 | 8 |

| Number of parts | 1,000 | 1,000 | 1,000 | 1,000 |

| Beveling / Machining required ? (Yes/No) | Yes | Yes | Yes | No |

| Additional cost of preparation per part | € 10 | € 14 | € 10 | € 0 |

| Number of passes per weld | 2 | 3 | 2 | 1 |

| Total combined welding length per part (meters) | 16 | 24 | 16 | 8 |

| Welding speed (m/min) | 0.60 | 0.25 | 0.70 | 1.00 |

| Total welding time per part (minutes) | 27 | 96 | 23 | 8 |

| Labor cost/part (average manpower cost €/h 40) | 17.78 € | 64.00 € | 15.24 € | 5.33 € |

| Cost of material, wire, gas, flux (per part) | € 6.67 | € 6.00 | € 4.47 | € 2.07 |

| Heat Input (KJ/cm) | 17 | 24 | 13 | 10 |

| Additional cost of straightening post welding | High | High | Medium | Low |

| Total cost per part | € 34.45 | € 84.00 | € 29.71 | € 7.40 |

| Total Cost - 1000 parts | € 34,448 | € 84,000 | € 29,708 | € 7,403 |

| Saving by using SuperMIG | € 27,044 | € 76,597 | € 22,305 | € 0 |

| Cost saving by using the SuperMIG (%) | 79% | 91% | 75% | |