SuperMIG®

SuperMIG® Overview

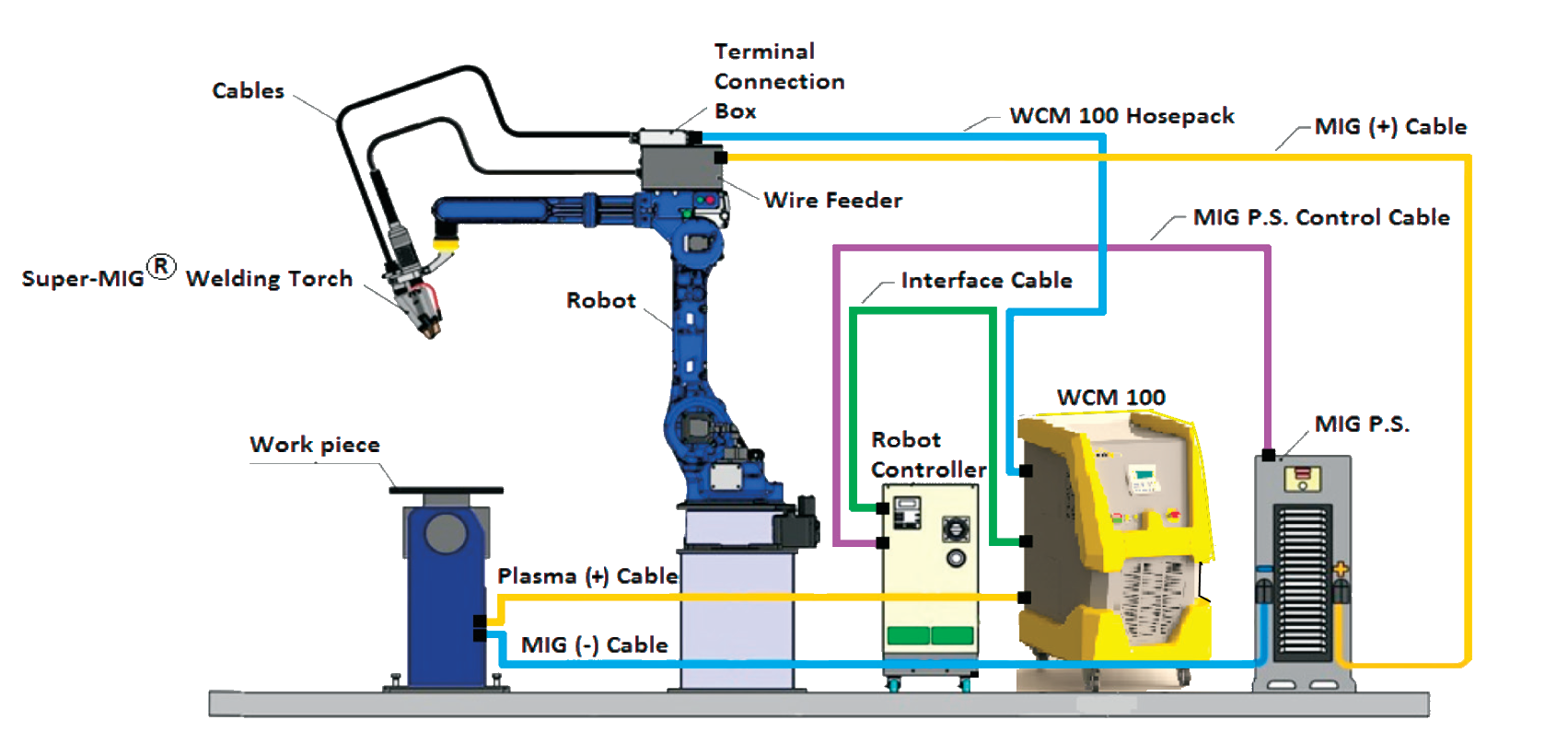

The SuperMIG® welding system is based on a unique combination of the Plasma Arc Welding (PAW) and Gas Metal Arc Welding (GMAW) processes and is protected by a registered patent. The system is composed of two main components: the Welding Torch (SuperMIG® WT) and the Welding Control Module (SuperMIG® WCM).

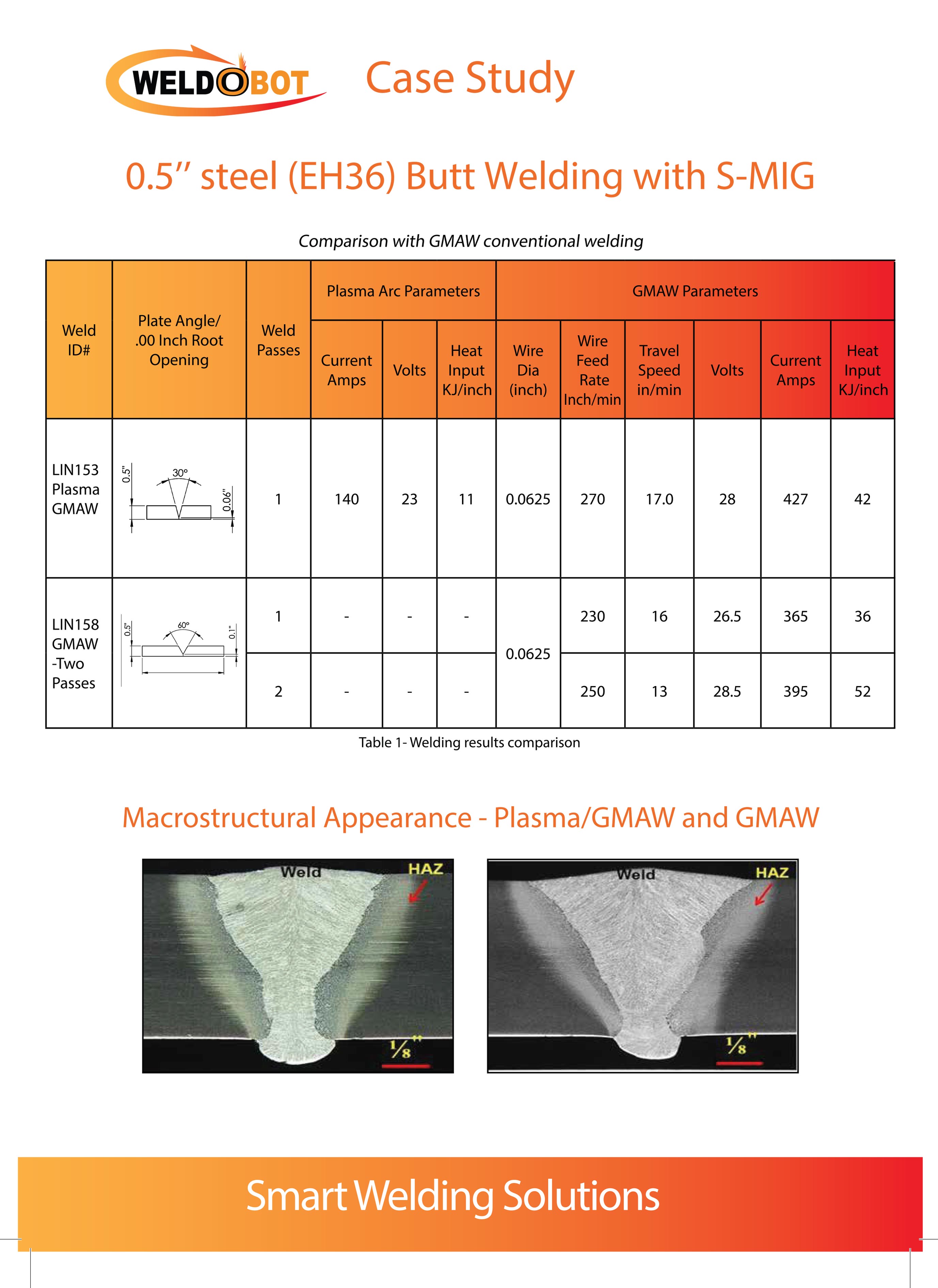

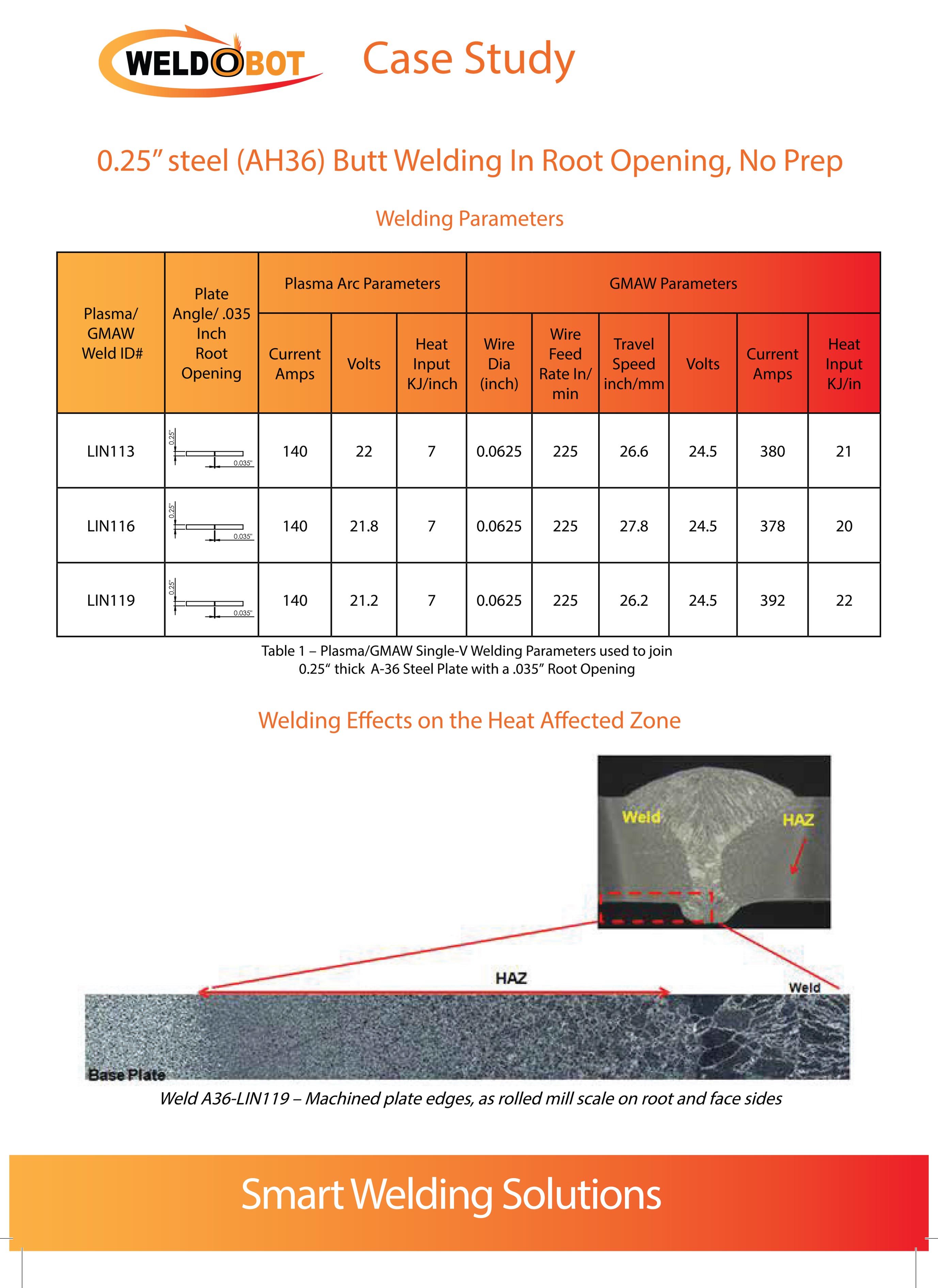

The resulting SuperMIG is a process that pairs the key advantages of both processes, deep penetration from the PAW arc, and high-deposition and arc efficiency from the GMAW arc. This unique combination allows for increased welding speed under variable root opening conditions, deeper weld penetration, and a narrower Heat-Affected Zone (HAZ).

System Configuration

Welding Control Module (SuperMIG® WCM)

The SuperMIG® WCM controls the welding parameters of the plasma process and can act as the master control if needed. It contains the plasma arc power source, as well as the pump and reservoir for the closed-loop cooling system, and controls and monitors the welding gas flowrates during welding. The SuperMIG® WCM was designed to be compatible with a wide variety of robot controllers, and a touchscreen user interface enables the operator to save multiple pre-defined weld schedules.

Contained within the unit, and integral to the SuperMIG® technology, is a patented SoftStart™ Arc Ignition Device. The device eliminates the effect of the electromagnetic interference during the establishment of the plasma pilot arc. This technology also substantially increases the life span of the tungsten plasma electrode.

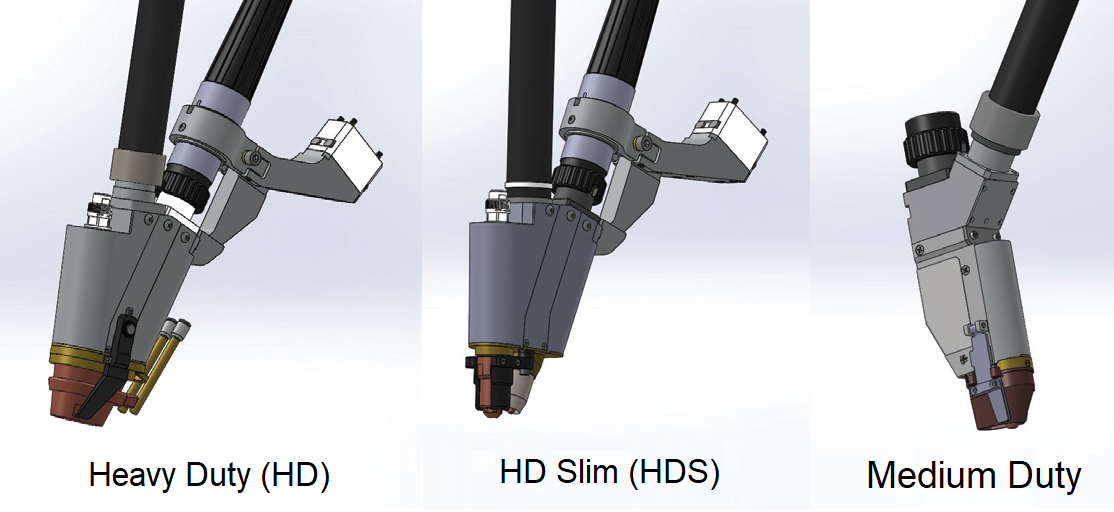

Welding Torchs (SuperMIG® WT)

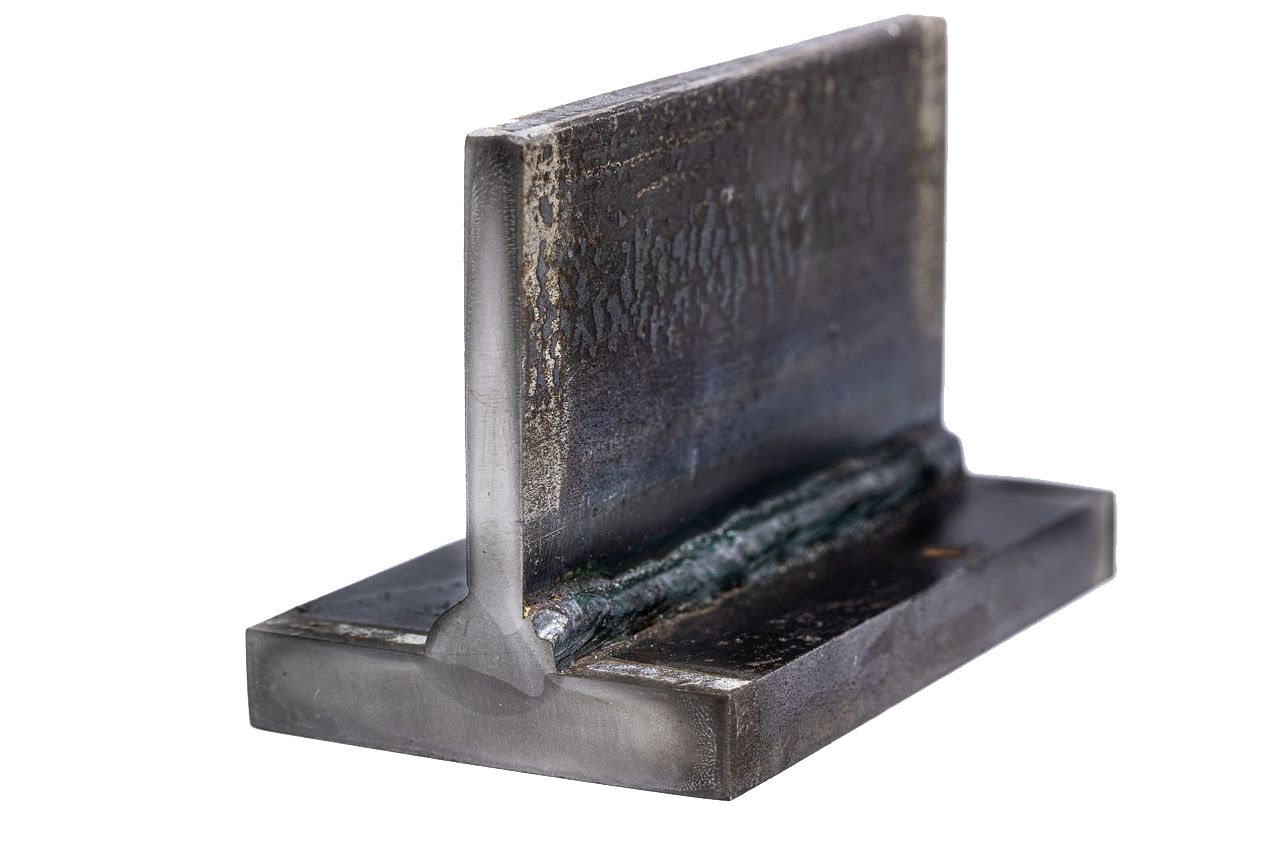

The SuperMIG® WT can accommodate filler wire diameters of up to 0.0625” (1.6 mm). Its welding head is electrically insulated, water cooled and pre-aligned, ensuring repeatable performance and easy maintenance.

The SuperMIG® WT family includes various models such as HD (Heavy Duty) and MD (Medium Duty), as well as custom heads to meet special material and geometry requirements.

Main Features and Capabilities:

Fast welding and better throughput:

Single-sided welding – no need for two sided operations

Single-pass welding of up to ½ inch (12 mm) thick steel

No edge preparation or beveling required

Filler metal consumption is decreased by over 50%

50% improvement in productivity

Quick return on investment

Welding Codes compliance

WELDOBOT’s SuperMIG® was designed to produce quality welds on a variety of ferrous-based alloys and in wide array of welding conditions.

SuperMIG® welds are regularly tested by 3rd party laboratories, such as TUV Nord – Germany/Poland, Metallabs/Applied Metallurgy – Israel, and Henry J. Yeager Laboratories – United States, and continue to produce satisfactory tensile, guided-bend, hardness, and impact test results.

SuperMIG® welds have satisfied the PQR (Procedure Qualification Record) requirements of various welding codes including, but not limited to, ISO 15614-1 Specification and Qualification of Welding Procedures for Metallic Materials, ASME Boiler and Pressure Vessel Code – Section IX Qualification Standard for Welding, Brazing, and Fusing Procedures; Welders; Brazers; and Fusing Operators, and AWS D1.1 Structural Welding Code – Steel.

Product Specifications:

S-MIG® WCM (Welding Control Module) Specifications | ||

| Medium Duty | Heavy Duty |

Loading capacity – 100% load | 200A/28VDC | 360A/28VDC |

Welding Gases Requirements | ||

Gas pressure | 4-6 bar (58-87psi) | |

Gas flow rate | 15 LT/min Argon | |

Gas type | Plasma Gas - Argon (welding grade) | |

Cooling liquid flow rate and pressure | 2.1 LT/min @ 7.5 Bar | |

Cooling Liquid Capacity/volume, L (Gallons) | 7.5L (2 USG) | |

Operation temperature range | 5°C (41°F)…. 45°C (113°F) | |

Storage temperature range | -10°C (13°F) … 55°C (131°F) | |

Electrical connection | 3 Phases 400V-10%,+6%, 50-60Hz, 5 pin connector | |

Power supply | 8.5 kVA @ 100 % duty cycle | 25 kVA @ 100 % duty cycle |

Max. External Dimensions – S-MIG®, WCM mm (Inches) | Depth : 940mm (37.0”) | |

S-MIG® WCM Max. Weight, Kg - (Lbs) | >150 kg.(331Lbs.) | |