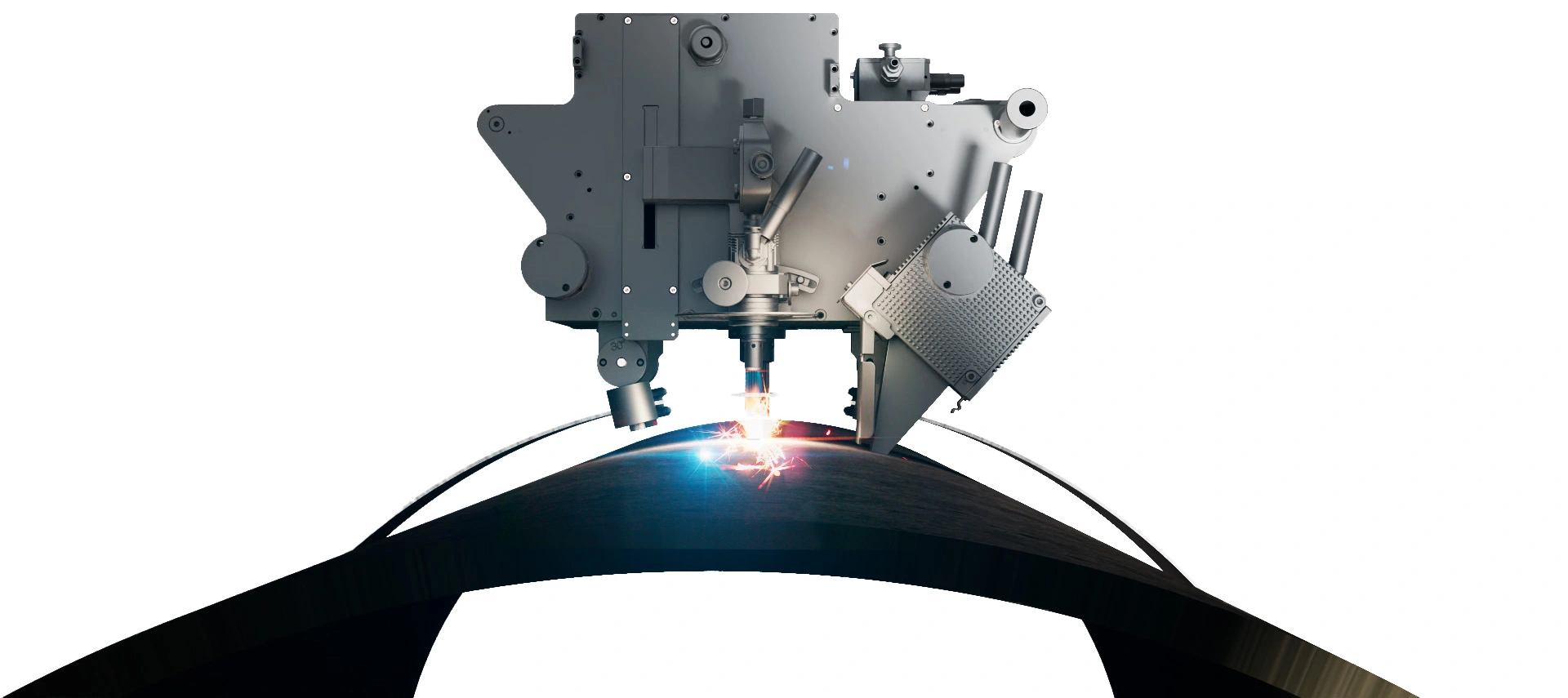

Autonomous Welding is Here

Introducing the most advanced technology ever integrated into a welding robot

Weldobot develops cutting-edge welding solutions that leverage advanced robotics and automation, powered by artificial intelligence. We specialize in welding long and thick metals, as well as orbital pipe welding, in demanding industrial and outdoor environments.

By integrating AI, sensors, software, and safety features, Weldobot delivers the world’s most advanced fully autonomous welding technology. Our proprietary, patented AI system enables robots to autonomously collect data, learn, process it, and continuously enhance welding performance to an entirely autonomous level.

How it works

Pre-Process

- Access previous results data

- Access universal database

- Use historic welding parameters

In Process

- Measure real-time progress with peripheral sensors

- Process using AI analysis algorithm

Post-Process

- Use X-ray or ultrasonic sensors to assess the finished product

- Feed AI-processed data back into database for next pre-process

Optimize, Correct, and Eliminate Errors through Motion Adjustments on the fly

Analyzing real-time welding data

AI empowers machines to collect and utilize data through advanced knowledge and sensing capabilities. By learning, processing, and adapting, Weldobot elevates welding performance, achieving a fully autonomous level.

Monitoring over 30 parameters includes among others:

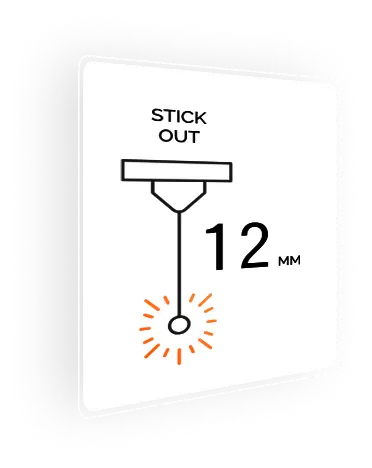

Measuring the stand-off distance

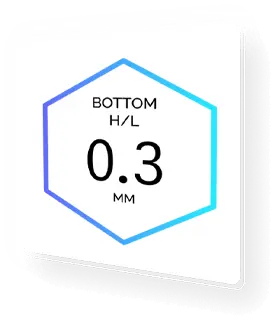

Locating the exact weld seam center

Monitoring peripheral conditions, such as heat during welding

Using a camera behind the welding torch to capture real-time images of the welding results