Autonomous Robot

for Orbital Welding

®

The First AI-Driven Autonomous Robot for Orbital Welding of Pipelines

AROW® Overview

In the ever-evolving landscape of pipeline construction and maintenance, the AROW® robotic welding system sets a new benchmark for innovation. This next-generation solution, powered by cutting-edge AI technology, transforms the welding process by significantly enhancing efficiency and productivity in the demanding pipeline industry.

AROW® is engineered to enable two robots to work simultaneously on the same pipe head, dramatically reducing operational time and increasing throughput. Its

innovative casing structure design not only safeguards the equipment but also

simplifies the welding process, making it user-friendly even for operators without

extensive professional welding expertise. This combination of features streamlines operations while ensuring exceptional quality and consistency in welds.

The development of AROW® is rooted in extensive field experience, gained through close collaboration with our parent company, Chemo Aharon Ltd., a trusted leader in pipeline contracting.

How it Works

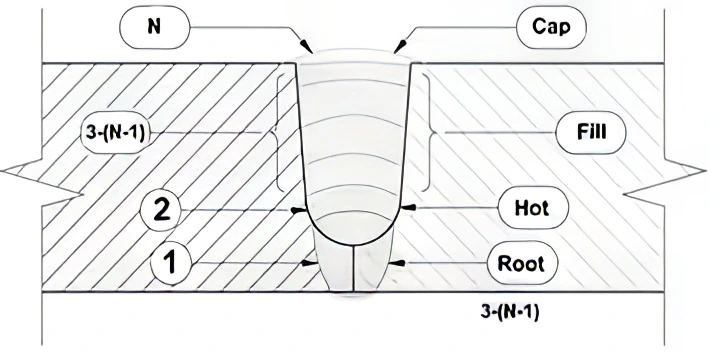

A gas pipeline is constructed from long, thick-walled segments. Before being attached and fitted, the pipes undergo a beveling preparation, typically in a V or U shape.

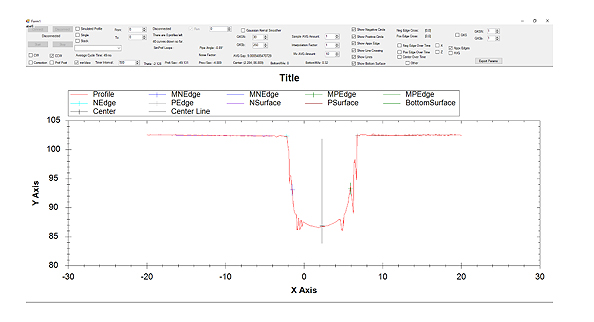

Multiple welding passes are required, including the root pass, hot pass, filling passes, and cover passes. With AROW, the bevel shape and topography of each pass around the pipe’s perimeter are scanned and measured using a line laser scanner.

Simultaneously, welding parameters are calculated based on the robot’s location data, an AI-developed algorithm, and statistically gathered information. The welding torch then moves to the precise position, executing the weld flawlessly with these optimized parameters.

Features and Benefits

Advanced Laser Sensing Technology

AI-based laser scanning tracks seam grooves in real time, enabling precise data collection and analysis.

Welding Power Source

Uses GMAW (MIG) welding for pipe segments with diameters starting from 12 inches and larger, supporting both uphill and downhill welding.

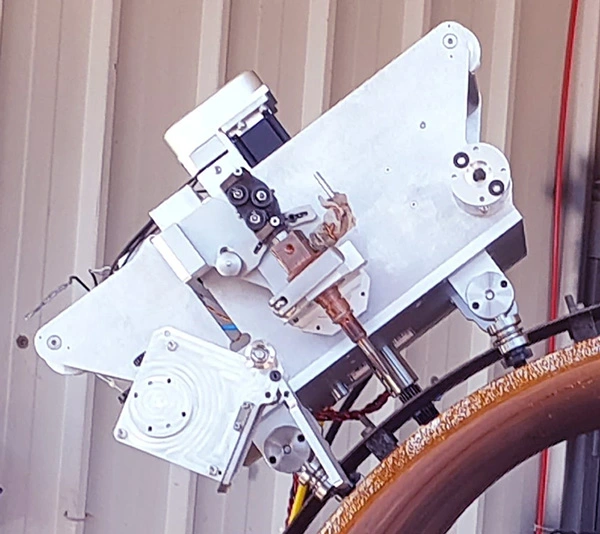

Servo-Controlled Motion

Features a closed and sealed system housing three servo-controlled motion axes: rotary (θ), horizontal (Y), and vertical (Z), ensuring precise movement and operation.

Automatic Wire Feeder

Equipped with a servo-controlled wire feeder that maintains consistent wire feeding during welding.

Mobility & Positioning

Moves on a toothed ring for accurate tracking and positioning around the pipe.

Operator Interface

Easy installation with a remote control pendant and operator/technician screens, requiring minimal expertise.

Dual Robot Operation

Two robots can work simultaneously on the same pipe for increased efficiency and productivity.

Durability & Reliability

Designed for rugged outdoor environments with high reliability and productivity. Minimal and easy maintenance required.

Control & Detection Systems

Includes an angle detection system for precise welding and a line laser scanner for enhanced real-time data collection.

Control Cabinet

Contains all essential electrical components and computer systems, ensuring smooth operation.

MIG Welding Torch

A MIG welding torch is installed on the robot arm for precise and automated welding execution.

AI Driving New Levels of Precision

in Orbital Welding

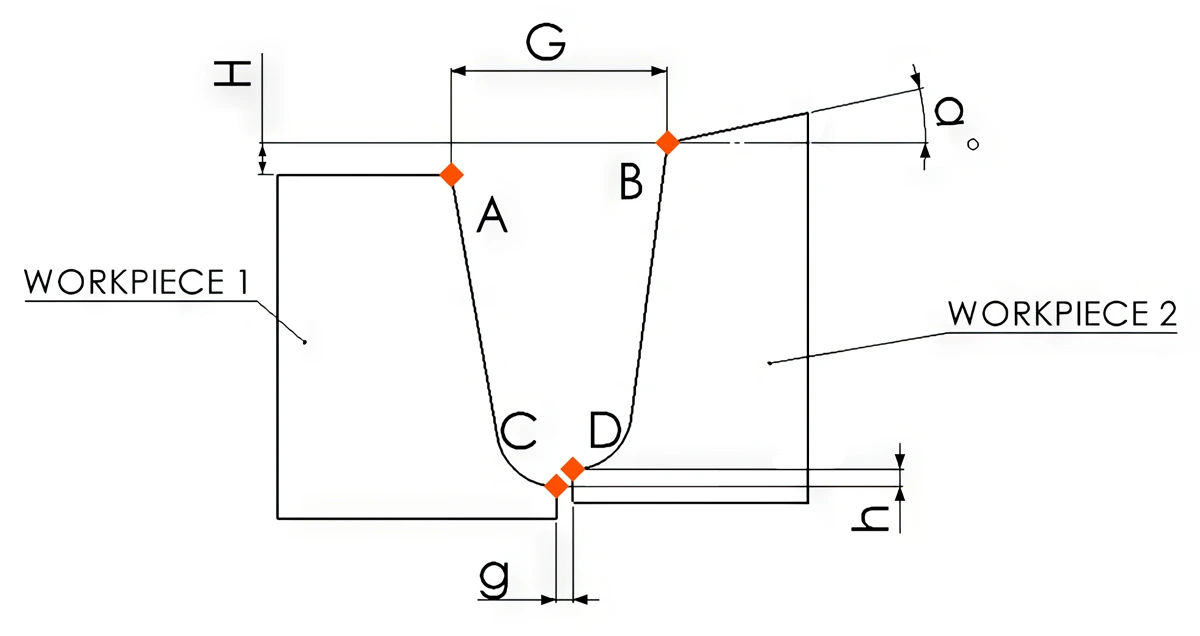

The challenge lies in accurately reading the groove while minimizing the measuring noise, analyzing the data, and filtering out disturbances caused by welding and reflections within the groove. Additionally, it’s crucial to align the laser readings with the position of the welding head. Key points in the groove, outlined below, provide the necessary information to ensure precise welding execution.

Upper High and Low points of the plates connection (A, B).

Bottom High and Low points of the plates connection (C, D).

Upper – High / Low between plates (H).

Lower – High / Low between plates (h).

Upper Gap between plates (seam Gap) (G).

Bottom gap between plates (g).

Robot position angle from the workpiece, workpiece deformation, and Manufacture malfunction. (α)

Veiling glare

Reflections caused by surface grinding

Welding light flashes

Welding drop spatter

Burn Through phenomenon.

Parameters controlled by AI-driven,

on-the-fly measuring and optimization:

- GMAW Current

- Arc length and Arc current

- Welding wire speed

- Oscillation (Y-Axis)

- Oscillation amplitude and frequency

- Welding height ( Z-Axis)

- Welding speed

AROW Specification

| Robot | Pipe Diameter | 300 mm (12") and up |

| Thickness welded pipe | 5 – 32 mm (other optional) | |

| Pipe material | Carbon Steel (other optional) | |

| Welding Type | GMAW (MIG) | |

| Ambient temperature | -20 – 55°C | |

| Welding speed | 2 – 20 mm/sec (other optional) | |

| Travel speed | 2-100 mm/sec (other optional) | |

| Weight | 22-25 kg | |

| Dimensions | H-35 cm / W-47 cm / L-45 cm | |

| Tracking system | Laser line tracker | 40 mm |

| Positioning accuracy | +/- 0.2 mm | |

| Grove profile | J & V groves | |

| Welding Torch | Elevation (Z axis) | 64 mm |

| Motion perpendicular to seam (y axis) | 64 mm | |

| Welding oscillation | 0-4 Hz (parameter setting) | |

| Amplitude – welding oscillation | 0-18 mm (parameter setting) | |

| System includes | AROW system | In protective box |

| Welder Teach pendant | Including | |

| Operator HMI screen | Including | |

| Control cabinet | Including | |

| Toothed band | Including (According to pipe dia.) | |

| GMAW PS | Optional | |

| Gas Mixer | Optional | |

| Working cabinet | Optional (indoor or outdoor) | |

| Welding wire | Wire feeder speed | 14 m/min |

| Welding wire type | Solid / FluxCored | |

| Welding wire size | 1-1.2 mm | |

| Power consumption | Operation Voltage | 100-240 VAC / 50/60 Hz |

| Max Power consumption (2 robot system) | 750 AV |

AROW Comparison table

| 36" pipe diameter / 19 mm thickness | |||

| AROW Welding system | |||

| No. Of welding cabin | 3 | cabins | |

| Cabin # | Cabin 1 | Cabin 2 | Cabin 3 |

| Welding layer | Root + Hot | F1 + F2 + F3 | Strip + Cap |

| Welding Time | 12 | 20 | 15 |

| Overall time for pipe section (all cabin works in parallel + overhead * time) | 30 -47 | min | |

| No. Of welders per day ( 2 per cabin) | 6 | Welders | |

| No. of sections per day ( 9 hr. shift) | 18 | Pipe/day | |

| Manual Welding | |||

| Professional welder | 2 | Welders | |

| No. Of sections per day ( 9 hr. shift) | 2 | Pipe/day | |

| Conclusions & Comparison | Manual Welding | AROW - Autonomous Welding | |

| No. Of welders for the same amount of pipe sections per day | 18 | 6 | |

| No of pipe sections per day | 2 | 18 | |

| MNP saving | 12 professional welders | ||

| Increases throughput | ~ 900% | ||

| Welding expertise | Professional | operators | |

* overhead Time including: fit-ups, grinding , and transitions between stations

Peripheral Products

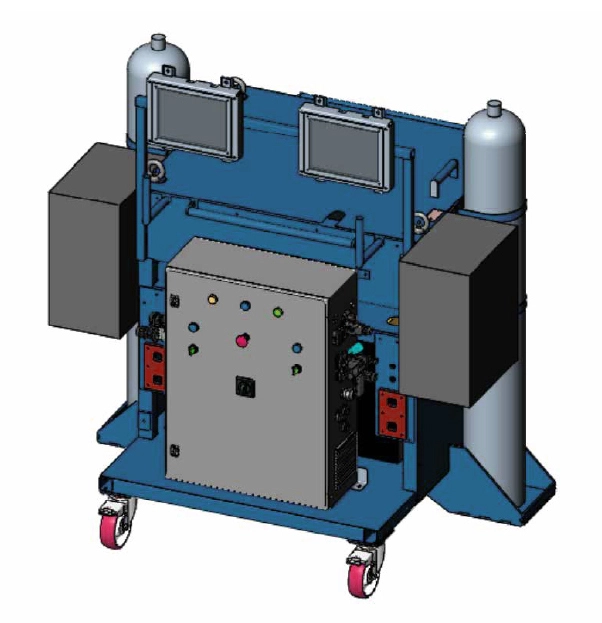

AROW Complete Welding Station

Indoor independent welding equipment and control cart

- Portable Carriage for indoor welding

- Supports 2 AROW systems

- Contains :

• Welding power supplies

• Gas cylinders

• Gas mixer

• AROW robot control cabinet

• Wire feeders

• Operator HMI screens

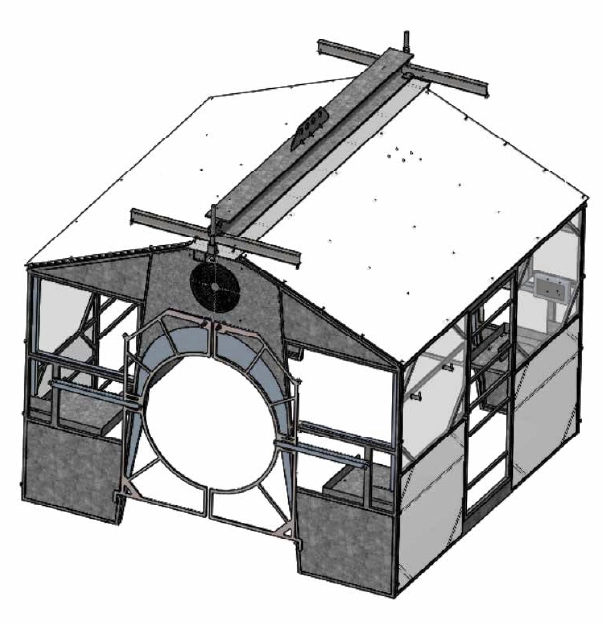

Outdoor Cabin

Designed for outdoor welding.

Modular, removable welding cabin.

Automatic openings for pipes when lifted and closed when on the ground.

Docking station for two AROW robots.

Integrated control cabinets.

Connecting cables to the lifting crawler for efficient mobility.